Repacking fee

The quantity you have requested will require us to break up a package. We charge a fixed fee for this per package.

Quantity can not be changed

Do you need more? Contact Customer service.

Components just as you want them

1. Toss ideas around with us.

We want our product specialists to feel like a natural part of your creative network. Whether you are a design student, small business owner or product developer for a large company, we hope that you will feel confident that our product specialists’ wide-ranging experience and broad network of contacts can help you to take your ideas forward.

2. Have us find existing solutions.

One simple solution may be for us to customise an existing standard product so that it has the right colour or logo. We call this a customised standard product.

Alternatively, we can see if any of our colleagues already have the solution you need. If we find it, we will provide you with a product recommendation and contact details.

3. Find out what it will cost to develop a completely bespoke component.

The following is a very short introduction to what normally happens when we develop a new plastic component.

Development costs.

Development costs tend to come to between 2000 and 20 000 Euro. This includes drawing checks, mould production, prototypes and more.

For the very lowest development costs, it is best if your specifications involve

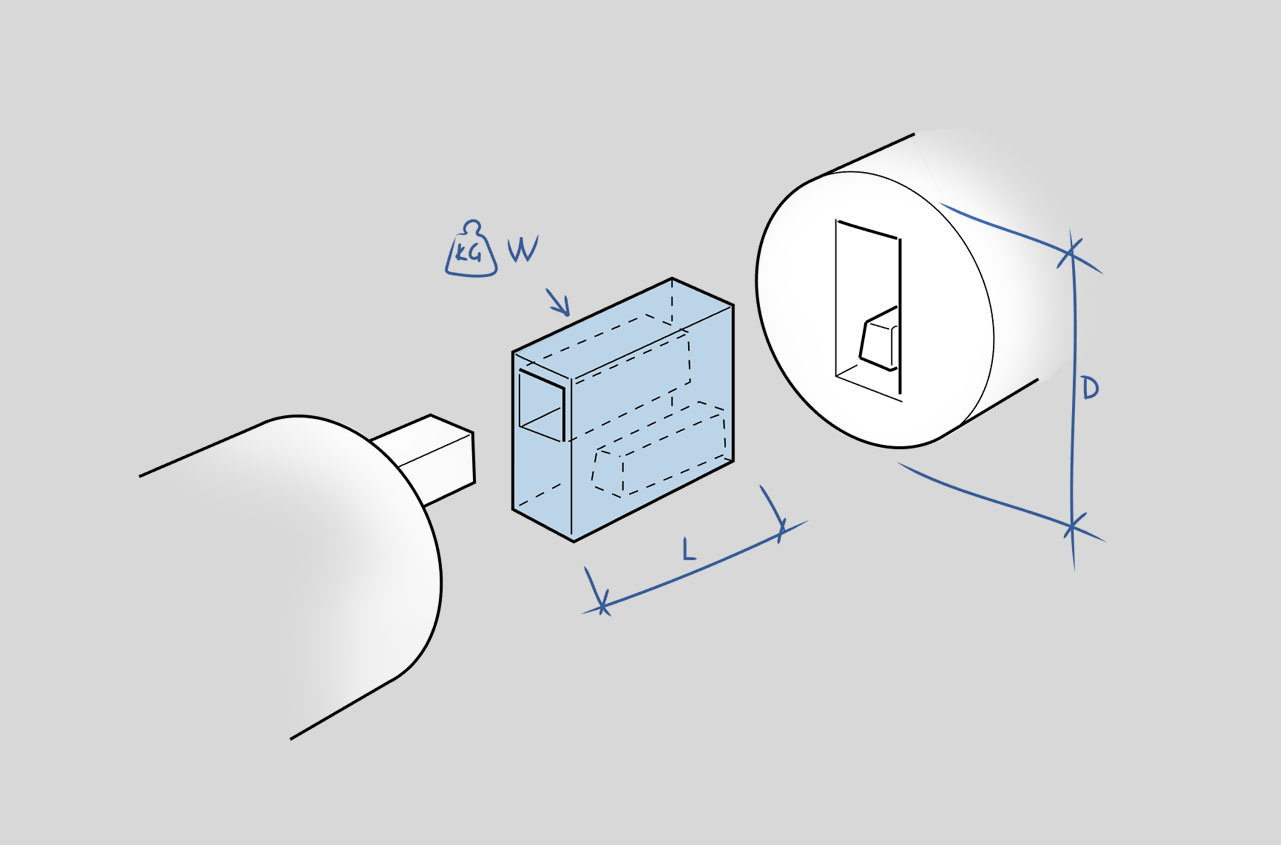

- a diameter of under 90 mm (D in the diagram below)

- a total component weight of under around 60 g (W in the diagram below)

- holes only in the pulling direction

- a component length of under around 200 mm (L in the diagram below)

However, for the very lowest component costs, it is best to make a bigger, more expensive mould that can produce multiple components simultaneously.

Development time

You can normally expect the first component delivery within 2–6 months. We can normally produce simple moulds, such as those in the diagram below, very quickly.

Component price

If thousands of components are being produced, but in a large mould that can produce many simultaneously, the component price normally comes to around 5 Euro cent.

If only a few hundred components are being produced but the mould is fairly simple, the component price will instead come to a arrond 50 Euro cent.

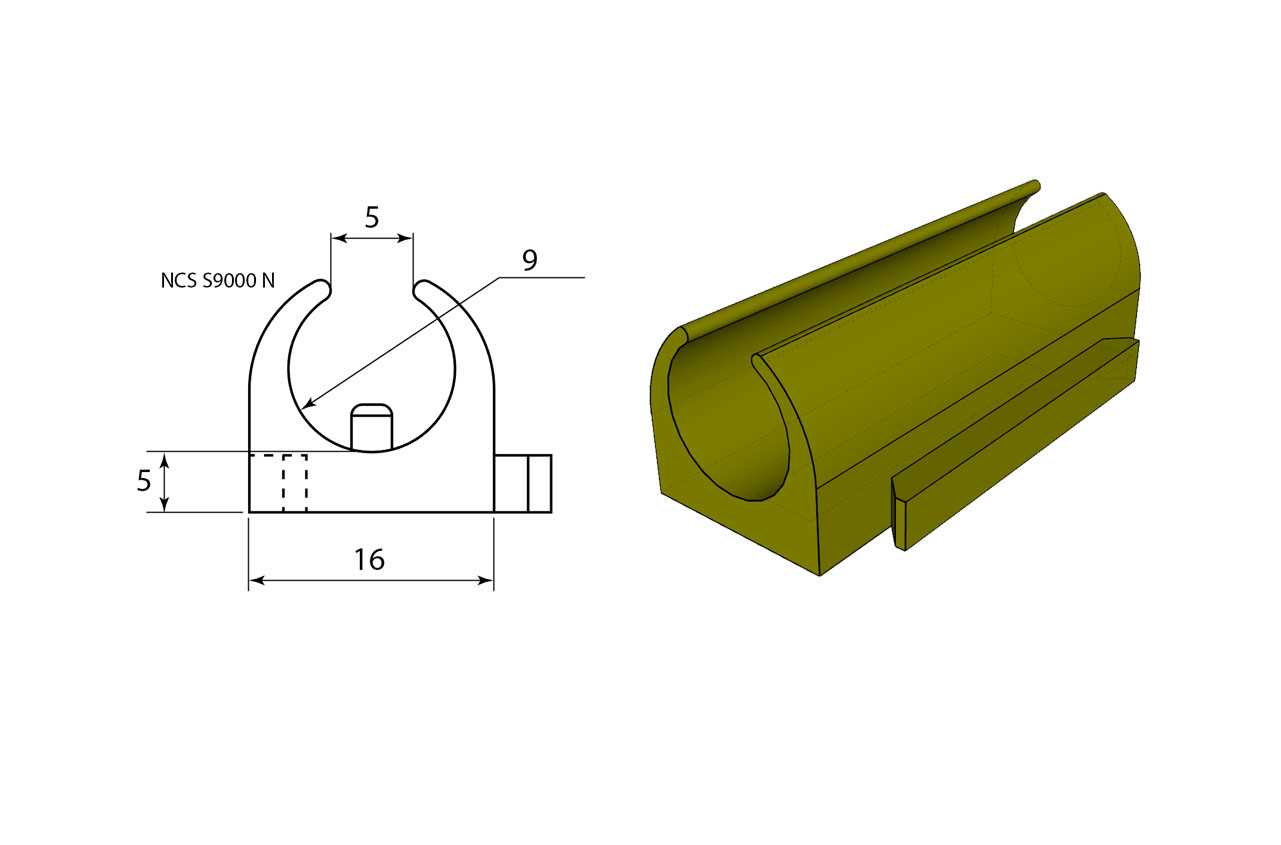

Illustration of our own system for moulding tool inserts. Inserts are available in both 70 mm and 90 mm.

4. Who do you contact?

Always speak to one of our product specialists...this is where they are best. Find their contact details here>>

Illustration of our own system for moulding tool inserts. Inserts are available in both 70 mm and 90 mm.

Here is an example of a customer uniqe armrest with a 40% sawdust mix. Nice feeling, scent.